Stainless steel, ceramic and foil swimming pools.

Swimming pools made of stainless steel have recently become popular on the market.

Due to rather high costs of construction, they are usually chosen as public pools or hotel pools.

We use AISI 316L stainless steel to make swimming pool basins. Every element that is in contact with water in the pool is produced in accordance with the STN 17 349 standard (DIN 1.4404) (AISI 316L).

The construction of the stainless steel swimming pool consists of the following steps:

1. Foundation.

Is all begins with setting walls of the pool on the previously prepared bottom plate and then anchoring them to concrete.

2. Pouring the second layer on the bottom plate.

After bottom channels and drain have been installed, comes the time to pour the last layer of the bottom plate. Then, a stainless steel basin is attached.

3. Final installation.

When the basin is installed, we grind and clean all welds and check the permeability of the surface coatings. The next step includes assembling technological solutions. After that we clean the basin, check for leaks once again and start using the pool.

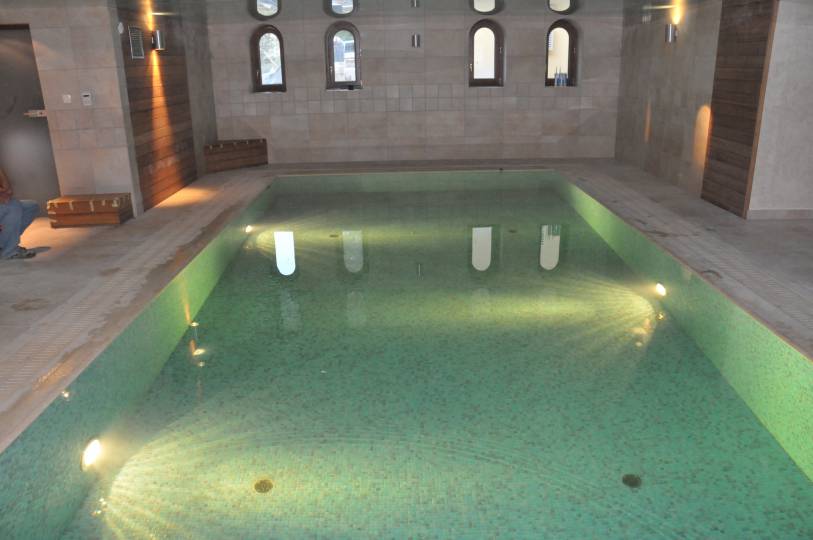

Ceramic pools

This type of pools require a load of work and financial means. First a reinforced monolith basin is prepared. To ensure leak-tightness of the basin we use proper sealing compounds. The basin needs to reach certain level of hardness before the ceramic (tiles or mosaic) will be laid. Taking it into consideration, it is recommended to wait up to 6 months until the basin reaches its hardness.

This kind of swimming pools requires using only materials designed for pools (tiles, mosaic, construction chemicals).

In our climate conditions, we most often advise that ceramic pools should be built indoors.

Foil swimming pools

The basin which will be filled with foil needs special preparation. Usually the basin is made of concrete blocks (depending on size or changing depth, the basin can also be made of concrete). It is crucial that walls and the bottom of the tank remain as smooth and even as possible. Thus, it is common to use self-levelling compounds. The basin is separated from the foil by geotextile layer. The last step is mounting and sealing the foil. We use DLW or ALKORPLAN swimming pool foils having a thickness of 1,5 mm. Foils are available in a variety of colours.